The Alchemy of Time

A journey through seven stages of obsession. Transformative engineering, from base element to horological artifact.

The Raw Source

Curation of Substance

Every commission begins with a solid billet of aerospace-grade metal. While others use flimsy stamped sheets, we select 316L Surgical Stainless Steel for its permanence and luster. For those seeking the technical edge, we offer Grade 5 Titanium and Precious Metals.

The Mirror Plane

Absolute Preparation

To capture light, the surface must be flawless. Each dial blank is hand-lapped using microscopic diamond compounds. We achieve a level of flatness that ensures the laser's focus never drifts, resulting in edges that are sharp at the atomic level.

The Digital Soul

Mathematical Translation

Your design is breathed into life through thousands of individual vectors. We manually program the path of light, optimizing every movement to manage heat and preserve the molecular integrity of the metal. This is where art meets pure mathematics.

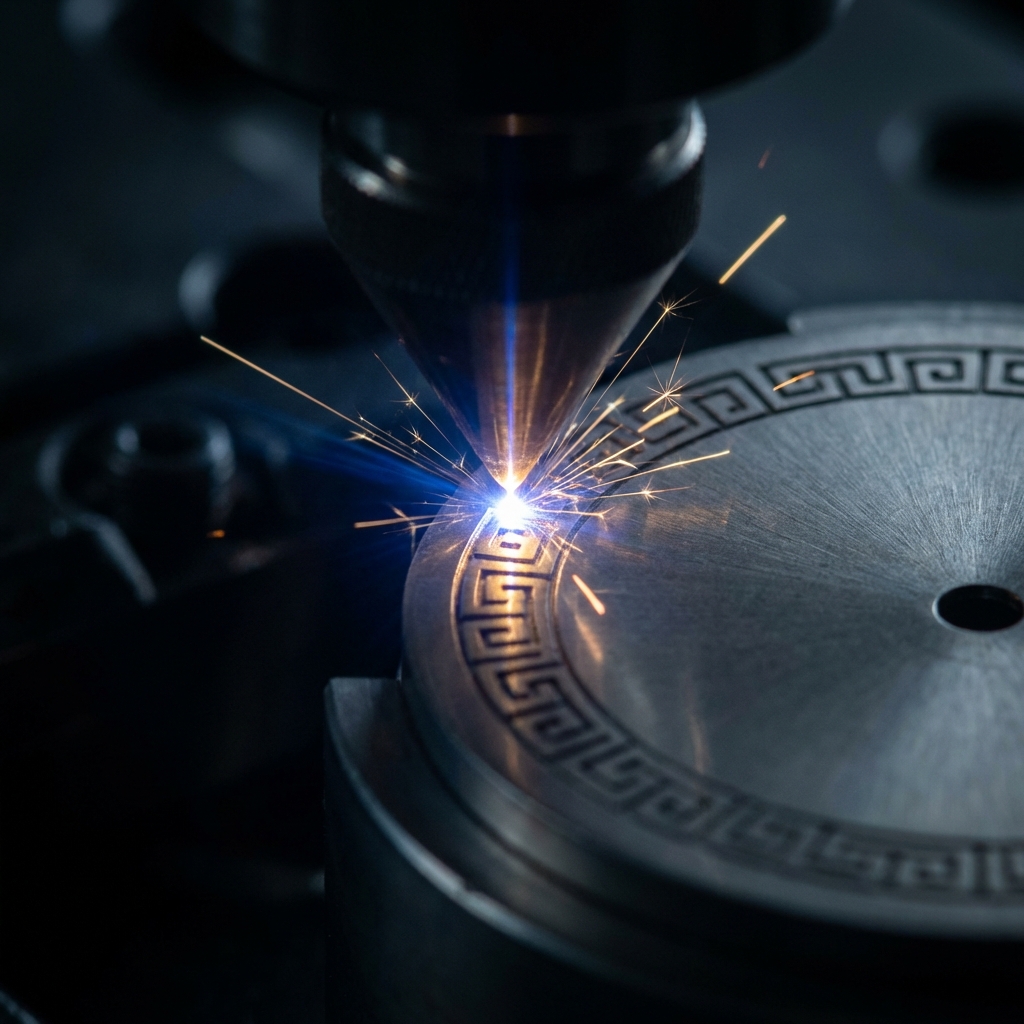

Subtractive Sculpting

The Core Transformation

We do not "mark" or "print" on the metal. We use high-energy light to vaporize it. By removing the background, your design rises in a deep, 3D relief. This creates physical depth that catches light and shadows in a way no flat dial ever could.

The Spectrum of Light

Molecular Expression

Color at PiDials is a physical achievement. On Titanium, we grow oxide layers that reflect light in vibrant gradients. On Steel, we create distinct textures—Matte, Satin, and Gloss—that define visual "colors" without a single drop of paint.

Atomic Perfection

Metrological Verification

Before leaving the lab, every dial is CNC machined to its precise diameter. We then perform a 50-point inspection to a tolerance of +/- 0.01mm. This ensures that every dial fits its movement with the exactitude required by high horology.

The Final Union

Horological Heritage

The journey concludes at the watchmaker's bench. Your custom-engineered dial is carefully paired with its movement, hands, and case. This is where modern laser engineering meets centuries of traditional craftsmanship.

Forged For You

Every alloy has a story. Every finish is intentional.

316L Stainless

The industry standard for a reason. Exceptional corrosion resistance and a cold, clinical luster perfect for monochromatic designs.

Grade 5 Titanium

Aerospace grade. The only material capable of achieving vibrant structural color gradients through our proprietary laser oxidation.

Legacy Alloys

From the warmth of C360 Brass to the timeless prestige of 18k Gold. We work with materials that carry historical weight.

"We choose the difficult path of subtractive light, because true luxury is not automated—it is engineered."

While the industry favors speed and volume, PiDials relies on time and precision. We are not just making dials; we are sculpting permanence.

Begin Your Journey